In the world of manufacturing, efficiency and cost are the ultimate goals to pay attention to. One of the main strategies to achieve this goal is through bulk production. But what exactly is bulk production, and how does it work?

This article will explain bulk production, from core concepts to implementation and considerations. Whether you’re an entrepreneur starting a new product line or simply curious about the world around you, this guide will give you everything you need to know about bulk production.

What is Bulk Production?

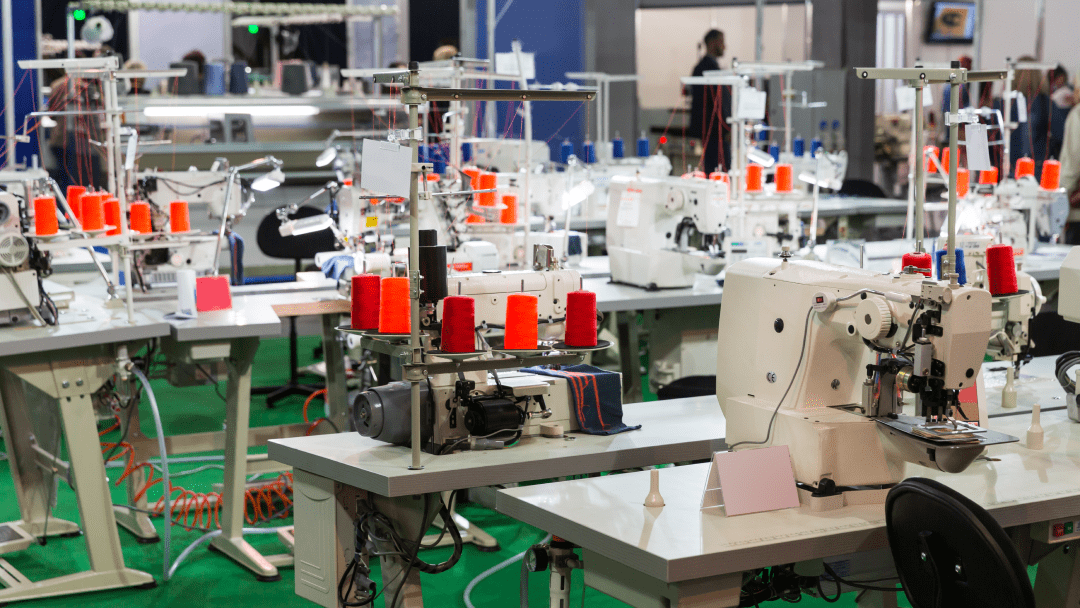

Bulk production is a manufacturing process for creating goods in large quantities, with a focus on efficiency and cost-effectiveness. Imagine a factory that produces countless thousands of t-shirts, that’s the essence of large-scale production.

This mass manufacturing process has several main aspects, including:

- High Volume: The core principle of high-volume manufacturing is that many identical units are produced. This allows manufacturers to achieve economies of scale, thereby significantly reducing unit costs as production volumes increase.

- Standardization: Every item in production must be the same. This means precise design, consistent materials like a specific type of plastic for those countless t-shirts, and repeatable manufacturing processes are crucial.

- Efficiency: Production on a large scale can thrive because of efficiency. Assembly lines, automation, and efficient workflows are key elements to ensure high yields and minimize waste.

Why Do Businesses Choose Bulk Production?

In today’s competitive market, efficient production methods can make or break a business. The following is an explanation of why high-volume manufacturing is the optimal choice for businesses that want to develop in modern trade.

1. Reduction of Cost Per Unit

When goods are produced in large quantities, economies of scale come into play. This means that the costs of raw materials, labor, and other overhead costs per unit can be minimized significantly.

For example, imagine a clothing manufacturer produces 1,000 units of a new design jacket. Let’s assume the unit costs might be $30 for materials, $15 for labor, and $5 for overhead, a total of $50 per jacket. If production were increased to 10,000 units, material and overhead costs would likely decrease due to bulk purchases, potentially reducing the cost per jacket to $35, a 30% reduction. This cost reduction per unit is a key benefit of high-volume manufacturing.

2. Increase Efficiency

With repeatable and standardized workflows, production cycles can be adjusted to maximize output with minimal waste. Through repetitive workflows, workers become more skilled through repetition, specialized machines operate at optimal levels, and the overall time required to produce each unit is reduced.

3. Meeting High Demand

In today’s era, consumer preferences can change in an instant, therefore having the capacity to produce large quantities quickly to meet fluctuating consumer preferences. Through a system of producing at scale, businesses can build large inventories that ensure products are always available, minimizing stock-outs or production delays.

4. Supply Chain Leverage

Production using this system often results in stronger relationships with suppliers. Purchasing raw materials in larger quantities gives companies greater bargaining power, allowing them to negotiate favorable prices and terms.

5. Sustainable Growth

By exploiting the advantages of production on a large scale, the business world can open up new opportunities for sustainable growth. Lower unit costs, increased efficiency, and the ability to meet high demand create competitive advantages that can expand market share and customer loyalty.

Can You Guess What’s Bulk Produced?

Large-scale production is not limited to one industry. In fact, it touches almost every aspect of our daily lives. Here’s a glimpse of the various products created through large-scale production:

- Daily Necessities: From the t-shirts and jeans you wear to the sneakers and sandals on your feet, countless clothing items are produced in bulk quantities. Household items such as plastic containers, cutlery, and cleaning supplies also benefit from the efficiencies of high-volume manufacturing.

- Technology Needs: Electronic devices that we rely on, such as smartphones, computers, and televisions. By creating millions of identical components such as circuit boards and memory chips, manufacturers achieve economies of scale and bring this technology to a wider audience.

- Industrial Building Blocks: The invisible heroes of our infrastructure are often the products of large-scale production. Steel beams, pipes, and construction materials are all produced in large quantities to support the creation of buildings, bridges, and other important structures.

- Chemical Requirements: Many chemicals are used in everyday products, from cleaning solutions to medicines produced on a large scale. This allows for consistent quality and available supply for a wide range of industries.

- Food and Drink: Although some types of food are made by hand, most packaged foods and drinks rely on large-scale production. This includes bottled water, canned foods, and processed snack foods, all of which benefit from the efficiency and cost-effectiveness of high-volume manufacturing.

How Does Bulk Production Work?

After learning which products can be made on a large scale, you may also be curious about how high-volume manufacturing takes place. Here are the steps involved:

- Assembly Line

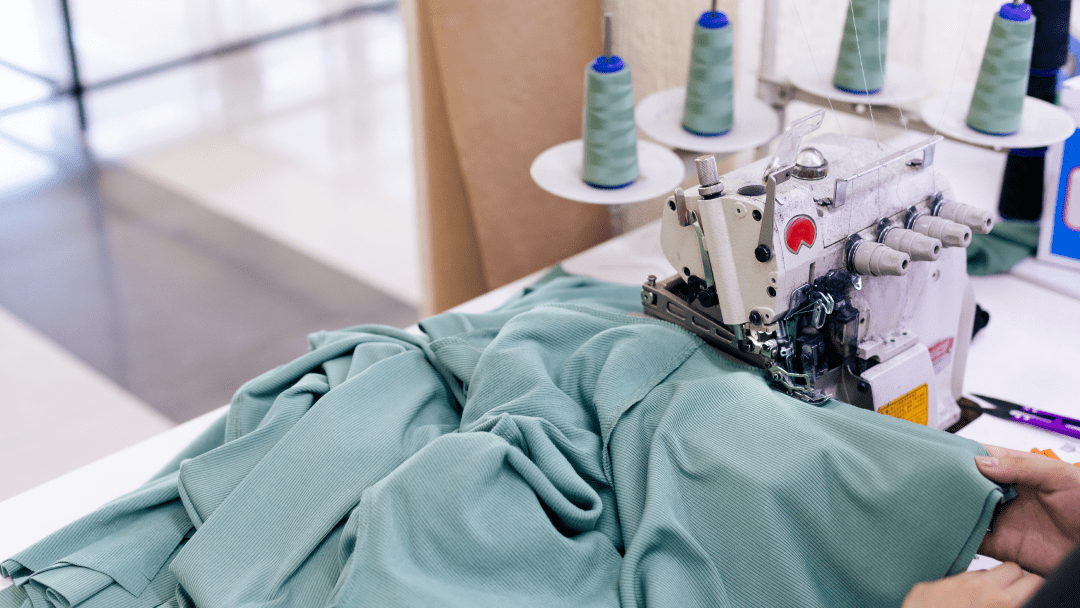

The assembly line involves two key concepts, sequential workflow and standardization. In a sequential workflow, products are created step by step, moving through a series of workstations where specialized tasks are performed. For instance, in clothing manufacturing, one station handles sewing while another is responsible for the design process. On the standardization line, each step is carefully monitored to ensure consistent quality. Every workstation specializes in a particular task, reducing errors and increasing speed. - Automation

Automation relies on two main technologies, robots and Computer Numerical Control (CNC). Robotic systems handle repetitive tasks with precision and consistency. They are frequently used to position small components in electronics manufacturing. CNC machines automate complex cutting and shaping tasks, transforming raw materials into precise parts with minimal manual intervention. This not only increases efficiency but also minimizes human error. - Quality Control

Quality control is essential to the high-volume manufacturing process. Inspection protocols involve periodic checks throughout production to identify defects early. Automated optical inspection systems use cameras and software to detect faults at high speed. Testing procedures are rigorous to ensure safety and functionality. This is especially critical in the pharmaceutical industry, where accurate dosages must be verified before delivery. - Supply Chain Management

A Just-in-Time (JIT) approach in supply chain management minimizes inventory costs by ensuring materials arrive only when needed. This reduces waste and simplifies storage. Collaboration with suppliers also plays a crucial role. Long-term partnerships guarantee a reliable flow of high-quality raw materials, ensuring smooth production. high-volume manufacturing thus relies on the seamless coordination of these key components to deliver quality goods efficiently and consistently.

Things to Consider When Choosing Bulk Production

Large-scale production offers many advantages, but it’s not a solution that can be applied to all businesses. Before deciding whether large-scale production is right for your needs, consider these key factors:

- Lead Time: High-volume manufacturing involves planning and organization. Lead time, namely the time needed from ordering to receiving finished goods, can be significantly longer compared to small-scale production. This is important to consider when planning your inventory and launch schedule.

- Minimum Order Quantity (MOQ): Manufacturers usually set the minimum order quantity (MOQ) for large-scale production runs. This means you have to commit to purchasing a certain amount of product upfront. Make sure the MOQ is aligned with your sales projections to avoid getting stuck with excess inventory.

- Customization Potential: While bulk production excels at creating identical items, customization options may be limited. If your product requires significant personalization, you should look for alternative production methods.

- Demand Forecasting: High-volume manufacturing thrives based on predictable demand. Accurately forecasting future sales is critical to avoiding overproduction or stockouts.

- Financial Investment: Setting up a large-scale production process can involve upfront costs for tooling, materials, and production setup. Therefore, carefully weigh these costs against the potential per unit cost savings of bulk production.

So, Is Bulk Production Right for You?

High-volume manufacturing offers an attractive combination of cost savings, efficiency, and scalability. However, it’s crucial to carefully consider the factors discussed in this guide before diving in. Nevertheless, when launching a new product line or meeting the high demand for existing products, bulk production can be a powerful tool for your business.

Interested in the power of large-scale production? OL Garments can help you ensure your production runs smoothly and successfully. For further information, you can visit the OL Garments website or contact us directly.

[FAQ]

1. What are the benefits of bulk production for garments?

Bulk production for garments offers several benefits, including cost savings due to economies of scale, consistent quality across a large number of items, and the ability to meet high demand efficiently. It also allows for better negotiation of material costs and streamlined manufacturing processes.

2. What factors should I consider when choosing a manufacturer for bulk garment production?

When choosing a manufacturer for bulk garment production, consider their experience, production capacity, quality control measures, lead times, and compliance with ethical and environmental standards. It’s also important to review samples and check references to ensure they can meet your specific needs.

3. How do I ensure quality control in bulk garment production?

Ensuring quality control in bulk garment production involves setting clear quality standards, conducting regular inspections at various stages of production, and working closely with the manufacturer to address any issues promptly. Implementing third-party quality audits and using detailed specifications and samples can also help maintain high quality.

4. What are the common challenges in bulk garment production?

Common challenges in bulk garment production include maintaining consistent quality, managing lead times, coordinating logistics, and ensuring compliance with regulations. Other issues can involve communication barriers with overseas manufacturers, fluctuating material costs, and unexpected delays due to supply chain disruptions.

5. How can I optimize the cost of bulk garment production?

To optimize the cost of bulk garment production, focus on efficient design and material usage, negotiate favorable terms with suppliers, and streamline production processes. Investing in technology and automation can also reduce labor costs. Additionally, consider producing in regions with lower manufacturing costs, but balance this with the need for quality and reliability.