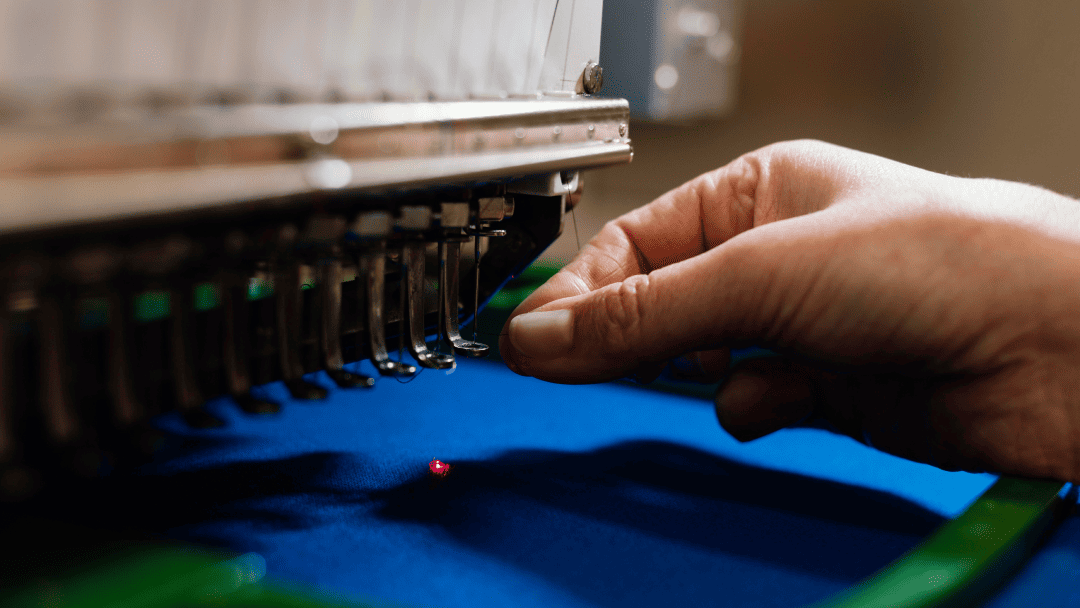

Custom embroidery manufacturers play a pivotal role in the textile industry, especially as demand for personalized and intricate designs continues to rise. The custom embroidery market has experienced significant growth, driven by trends in fashion, corporate branding, and personalized merchandise.

However, embarking on large-scale custom embroidery projects comes with its own set of financial challenges. From the high initial costs associated with setup and production to the ongoing task of managing cash flow, businesses must navigate these hurdles to achieve profitability.

Effective cost management is not just beneficial but essential for the success of these projects. By strategically planning and implementing cost-saving measures, companies can ensure they deliver high-quality embroidered products while maintaining financial stability.

Strategic Budgeting for Large Orders: Planning & Allocation

When working with custom embroidery manufacturers on large-scale projects, strategic budgeting becomes a critical component of success. Effective planning and allocation of resources can make the difference between a project that thrives and one that struggles under financial strain.

- Cost Estimation: Accurate cost estimation is essential. Custom embroidery manufacturers often provide quotes based on labor, materials, and overhead. Don’t forget to factor in hidden costs such as shipping, taxes, and any potential overtime pay for rush orders.

- Bulk Discounts: One of the significant advantages of large-scale projects is the ability to leverage bulk order discounts. Bulk discounts can significantly reduce the per-unit cost, making the project more financially viable. Additionally, consider negotiating long-term contracts to secure better rates for future orders.

- Material Choices: Selecting the right materials is crucial for balancing cost and quality. While it might be tempting to opt for the cheapest materials, this can compromise the final product’s durability and appearance. Discuss options like using blends instead of pure fabrics or sourcing materials from suppliers that offer competitive prices.

By focusing on strategic budgeting and meticulous planning, businesses can ensure their large-scale custom embroidery projects are financially sustainable. Engaging with custom embroidery manufacturers early in the process and maintaining open communication throughout the project can further enhance financial efficiency, leading to successful and cost-effective outcomes.

Request for Quotes (RFQ): Ensuring a Strategic Selection Process

Requesting and evaluating quotes (RFQs) from custom embroidery manufacturers is a crucial step that can greatly influence the success of your large-scale embroidery projects. This process not only helps you understand the cost implications but also gives insight into the capabilities and reliability of potential manufacturers.

1. Preparing a Well-Drafted RFQ:

- Detailed Specifications: Your RFQ should include all necessary details about your project. This includes the complexity of the design, specifying the intricacies and the type of embroidery required (e.g., 3D embroidery, appliqué, etc.).

- Material Requirements: Clearly outline the types of materials you want to be used, such as specific fabrics, threads, and any other components essential for your project.

- Order Quantity: Specify the total number of units you need, and if applicable, provide a breakdown of different sizes, colors, or variations.

- Timeline: Include your expected timeline for production and delivery, highlighting any critical deadlines.

- Quality Standards: Define the quality standards you expect, including any certifications or industry benchmarks that the manufacturer must meet.

2. Evaluating Responses

- Pricing: While cost is a significant factor, it’s essential to look beyond the initial price. Consider the overall value, which includes quality, reliability, and service.

- Value Offered: Evaluate what each manufacturer brings to the table. Do they offer additional services such as design assistance, sample production, or flexible payment terms?

- Responsiveness: The speed and detail of the manufacturer’s response can indicate their level of customer service and commitment. A prompt, detailed quote suggests a manufacturer that values your business and is willing to invest time in understanding your needs.

- Clarity and Comprehensiveness: A comprehensive quote should address all aspects of your RFQ, leaving no ambiguities. Clarity in communication reflects the manufacturer’s professionalism and their ability to execute the project as per your specifications.

3. Strategic Benefits of a Thorough RFQ Process

- Cost-Effectiveness: By comparing multiple quotes, you can identify the most cost-effective option that meets your quality and timeline requirements.

- Capability Assessment: Evaluating different manufacturers helps you understand their capabilities, ensuring that you choose a partner who can handle the complexity and scale of your project.

- Risk Mitigation: A detailed RFQ process reduces the risk of misunderstandings and errors, leading to smoother project execution and higher satisfaction.

In conclusion, a well-prepared and carefully evaluated RFQ process is instrumental in identifying the right custom embroidery manufacturer. It ensures you receive not only the best price but also the highest value, paving the way for successful and efficient project completion.

Collaborative Cost Reduction: Maximizing Efficiency with Custom Embroidery Manufacturers

Effective collaboration with custom embroidery manufacturers is not just about getting the job done; it’s about optimizing efficiency and reducing costs while maintaining high-quality standards. By fostering strong relationships and implementing joint cost-saving initiatives, businesses can achieve significant savings without compromising on product quality.

- Building Strong Relationships: Establishing solid relationships with custom embroidery manufacturers is key to long-term success. Beyond transactional interactions, investing in these partnerships fosters trust, transparency, and mutual understanding.

- Joint Cost-Saving Initiatives: Collaboration opens the door to innovative cost-saving initiatives. By working closely with manufacturers, businesses can identify opportunities to streamline processes, optimize workflows, and pool resources. Shared resources, such as machinery and equipment, can reduce overhead costs for both parties.

- Quality Assurance: While cost reduction is important, it should never come at the expense of product quality. Collaborative cost-saving initiatives should be accompanied by robust quality assurance measures to ensure that standards are maintained. Continuous monitoring, inspections, and quality control procedures help identify and address any potential issues before they impact the final product.

By embracing collaborative cost reduction strategies and fostering strong partnerships with custom embroidery manufacturers, businesses can achieve significant cost savings while delivering high-quality products. Through open communication, mutual respect, and shared goals, manufacturers and businesses can navigate challenges together, driving efficiency and innovation in the custom embroidery industry.

Empowering Collaboration for Cost-Effective Custom Embroidery Projects

In conclusion, effective collaboration with custom embroidery manufacturers is essential for navigating the financial challenges of large-scale projects while maintaining quality and efficiency. By prioritizing strong relationships, embracing joint cost-saving initiatives, ensuring quality assurance, and fostering clear communication, businesses can achieve significant savings without compromising on the excellence of their embroidered products.

As businesses seek reliable and high-quality embroidery manufacturers, direct engagement with trusted partners becomes paramount. OL Garments stands as a testament to quality and reliability in the industry. For comprehensive information on manufacturing services, including custom embroidery, reach out to OL Garments. Get in touch with OL Garments today to discover how their expertise can elevate your embroidery projects to new heights.

[FAQ]

- What services do custom embroidery manufacturers offer?

Custom embroidery manufacturers offer a range of services including digitizing artwork, custom design creation, embroidery on various materials, and finishing touches like trimming and packaging.

- How do I choose the right custom embroidery manufacturer for my needs?

Consider factors like experience, reputation, portfolio quality, production capacity, turnaround time, and pricing when selecting a custom embroidery manufacturer.

- What are the typical turnaround times for custom embroidery orders?

Turnaround times vary based on factors like order size, complexity, and manufacturer capacity. Typically, smaller orders may take days, while larger orders can range from weeks to months.

- Can custom embroidery manufacturers accommodate rush orders?

Some manufacturers offer rush order services for an additional fee. It’s essential to inquire about rush order availability and any associated costs before placing your order.

- How can I ensure the quality of custom embroidery work from a manufacturer?

Request samples, review their portfolio, read customer reviews, and ask about their quality control processes to ensure the custom embroidery manufacturer meets your standards.